1) Which safety rating is best for construction sites in Johor (S1P or S3)?For most construction sites, S1P or S3 is a safe starting point because sharp debris is common. S1P focuses on puncture resistance for dry-to-mixed sites. S3 is often chosen when the site is more demanding (mixed ground, wet areas, rough outdoor conditions). The best choice depends on your hazard list and ground conditions.

2) What is the difference between S1, S1P, S2, and S3 safety shoes?Think of ratings like “levels” of protection. S1 suits drier indoor work with basic protection. S1P adds puncture resistance (useful if nails and sharp scraps are present). S2 adds stronger water resistance for wet environments. S3 usually combines puncture resistance plus better outsole features for tougher, mixed site conditions.

3) Steel toe vs composite toe: which one should we choose for our team?Both protect the toes, but they feel different. Steel toe is a classic, strong option used widely. Composite toe is usually lighter and can be more comfortable for long shifts. If your team walks and stands for many hours, composite toe may reduce fatigue and complaints. Choose based on job demands, comfort goals, and site rules.

4) Do we need puncture-resistant midsoles for our site (and what types exist)?If your site has nails, rebar tie wire, metal scraps, or sharp debris, puncture resistance is strongly recommended. It helps prevent “through-the-sole” injuries, which are painful and disruptive. Common options include steel midsoles (durable, slightly heavier) and fabric/kevlar-style midsoles (often lighter and more flexible). Pick what fits your environment and comfort needs.

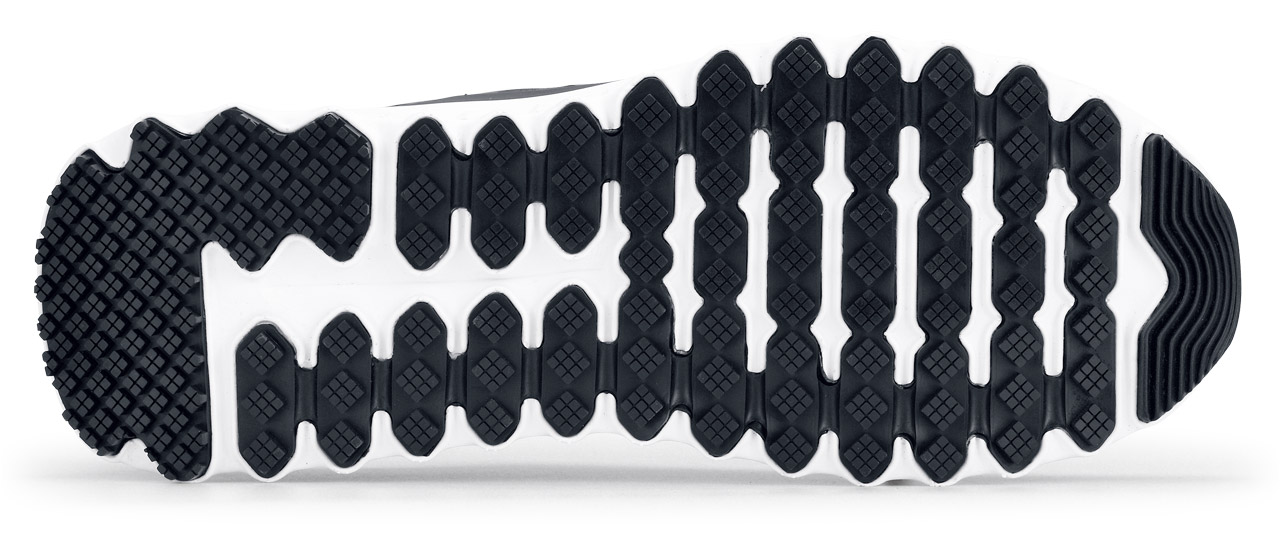

5) What slip-resistance features should we look for on wet or oily floors?Start with the outsole: slip resistance depends on rubber compound + tread pattern, not looks alone. For wet or oily areas (workshops, loading bays, factories), choose shoes designed for oil/slip conditions and avoid overly hard, smooth soles. A simple test is practical too: if the outsole feels like hard plastic, it often performs worse on slick floors.

6) What is ESD safety footwear, and who needs ESD shoes?ESD footwear helps control static discharge in controlled areas. It is common in electronics, assembly, testing labs, and sensitive production zones. If your workplace has marked ESD areas or requires static control, ESD shoes help protect components and reduce risk. If you do not have ESD requirements, standard anti-static footwear may be sufficient depending on policy.

7) How can we verify the shoes are genuine and compliant (labels, docs, certifications)?Ask for clear product identification that matches what you receive: model name/number, safety rating, and consistent labeling on the shoe, box, and invoice. A reliable supplier should be able to explain the rating and provide supporting documents or product info. If details are vague or inconsistent, treat it as a red flag before you place a bulk order.

8) Can we arrange sizing and fitting trials before a bulk purchase?Yes this is one of the best ways to reduce problems later. A fitting trial helps you confirm size accuracy, width comfort, and real-world feel during movement. Even a short on-site session can cut exchanges and complaints. It also helps you choose 2–3 models that most workers will accept, making standardization and reordering much easier.

9) Do you provide size exchange for bulk orders, and what are the rules?A good supplier should have a clear exchange policy. Before ordering, confirm the exchange window, whether shoes must be unused, and how they handle mixed sizes in bulk orders. The goal is to prevent delays during rollout. If the exchange process is unclear, run a fit trial first and order a smaller batch for confirmation.

10) How fast can you deliver across Johor (JB, Kulai, Pasir Gudang, Pontian), and what are the lead times for special sizes?Delivery speed depends on stock availability, order size, and cut-off time. For common sizes in stock, local delivery may be same-day or next-day. For large quantities, special sizes, or specific models, lead time may be longer. To avoid delays, standardize your models early and keep a small buffer stock of fast-moving sizes.

Safety shoes Johor is a common search for businesses and workers operating in one of Malaysia’s most active industrial regions. From manufacturing plants in Johor Bahru to warehouses and construction sites in Pasir Gudang, proper safety footwear is essential for protecting workers from daily hazards such as heavy objects, sharp materials, slippery floors, and long working hours.

Choosing the right safety shoes is not just about comfort it is about injury prevention, compliance, and long-term workplace safety.

What Are Safety Shoes?

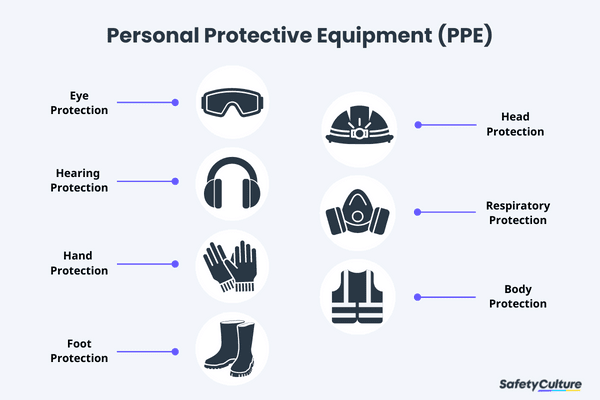

Safety shoes are a type of personal protective equipment (PPE) designed to protect the feet from workplace hazards. Unlike regular footwear, safety shoes are built with reinforced toe caps, slip-resistant soles, and durable materials that can withstand industrial conditions.

As part of a complete PPE system, safety footwear is often used alongside helmets, gloves, and protective clothing available within a full PPE range to provide layered protection in high-risk environments.

Why Safety Shoes Are Important in Johor Workplaces

Johor is home to factories, construction projects, ports, and logistics hubs where foot injuries are a common risk. Falling objects, sharp debris, oil spills, and uneven surfaces can cause serious injuries without proper footwear.

Using suitable safety shoes helps:

- Protect toes from impact and compression

- Prevent slips and falls

- Reduce fatigue during long shifts

- Support compliance with workplace safety requirements

According to Malaysia’s Department of Occupational Safety and Health (DOSH), employers are responsible for providing suitable PPE to protect workers from occupational hazards, including foot injuries. You can learn more about these responsibilities on the official DOSH website: https://www.dosh.gov.my/

Common Industries in Johor That Require Safety Shoes

Safety shoes are widely used across many industries in Johor, including:

Manufacturing and Production

Workers are exposed to heavy machinery, sharp materials, and long standing hours.

Construction and Infrastructure

Protection is needed from falling objects, nails, uneven surfaces, and wet conditions.

Logistics and Warehousing

Slip resistance and toe protection are critical when handling goods and operating forklifts.

Maintenance and Engineering

Safety footwear protects against electrical, mechanical, and environmental hazards.

Each industry has different risk levels, making proper shoe selection essential.

Types of Safety Shoes for Different Work Environments

Not all safety shoes offer the same level of protection. Choosing the right type depends on the work environment.

Steel-Toe Safety Shoes

Designed to protect against heavy impact and compression injuries. Common in construction and manufacturing.

Composite-Toe Safety Shoes

Lighter than steel-toe shoes and suitable for environments requiring metal-free footwear.

Slip-Resistant Safety Shoes

Designed for wet or oily surfaces commonly found in warehouses and kitchens.

Waterproof Safety Shoes

Suitable for outdoor work or environments exposed to liquids.

These options are commonly part of industrial safety equipment supplied to Johor’s industrial sector.

Key Features to Look for When Buying Safety Shoes in Johor

When selecting safety shoes, it’s important to look beyond appearance.

Comfort and Fit

Shoes should provide proper cushioning, arch support, and breathable materials especially important in Johor’s hot and humid climate.

Durability

High-quality materials ensure the shoes last longer under tough working conditions.

Sole Grip and Stability

Slip-resistant soles help reduce fall risks on wet or oily surfaces.

Compliance with Safety Standards

Safety shoes should meet recognized standards such as ISO or ASTM, ensuring reliable protection.

How to Choose the Right Safety Shoes in Johor

Start by assessing the hazards present in your workplace. Heavy machinery may require steel-toe protection, while wet environments need slip-resistant soles.

Next, consider how long the shoes will be worn each day. Comfortable footwear improves productivity and reduces fatigue. Many companies also coordinate footwear selection with customised workwear to ensure consistency, comfort, and professional appearance across teams.

Common Mistakes When Buying Safety Shoes

One common mistake is choosing safety shoes based on price alone. Low-quality footwear may wear out quickly or fail to protect properly.

Another issue is incorrect sizing. Poorly fitted shoes can cause discomfort, blisters, and long-term foot problems. Ignoring replacement cycles is also risky worn-out soles and damaged toe caps reduce protection significantly.

Benefits of Investing in Quality Safety Shoes

Using high-quality safety shoes provides several long-term benefits:

- Reduced workplace injuries

- Lower medical and compensation costs

- Improved worker comfort and morale

- Better compliance with safety practices

Working with suppliers that demonstrate a strong commitment to safety helps ensure consistent quality and reliable protection over time.

Choosing a Reliable Safety Shoes Supplier in Johor

A trusted safety shoes supplier in Johor should offer:

- A wide range of safety footwear options

- Products suitable for different industries

- Consistent stock availability

- Practical guidance on selection and sizing

Choosing the right supplier ensures that safety footwear supports both protection and productivity.

Frequently Asked Questions (FAQs)

Are safety shoes mandatory in Johor workplaces?

Requirements depend on the hazard level, but safety shoes are commonly required in industrial environments.

How often should safety shoes be replaced?

Replace them when soles wear out, toe caps are damaged, or comfort is reduced.

Are safety shoes comfortable for long working hours?

Modern safety shoes are designed with cushioning and breathable materials for extended wear.

Do safety shoes meet Malaysian safety standards?

Quality safety shoes meet international standards and support local safety compliance.

Final Thoughts

Choosing the right safety shoes Johor is a key step in protecting workers and maintaining a safe workplace. With proper selection, quality materials, and a reliable supplier, safety footwear becomes an essential part of an effective workplace safety program.

Coverall PPE Johor plays a critical role in protecting workers from daily industrial hazards such as dust, chemicals, spills, and contamination. In major industrial areas like Johor Bahru and Pasir Gudang, the demand for reliable coverall PPE Johor solutions continues to grow as workplaces prioritise safety, hygiene, and regulatory compliance.

Protective coveralls act as a barrier between workers and harmful substances, helping reduce health risks, improve productivity, and support safer industrial operations across manufacturing, construction, logistics, and maintenance sectors.

What Is Coverall PPE?

Coverall PPE refers to protective clothing designed to cover most or all of the body, providing a barrier between the worker and workplace hazards. Unlike regular uniforms, PPE coveralls are made from specialised materials that protect against dust, liquids, chemicals, and biological exposure.

As part of a complete PPE range, coveralls are commonly used together with gloves, safety footwear, respiratory protection, and head protection to create layered safety in high-risk environments.

Why Coverall PPE Is Important in Johor Industries

Johor is one of Malaysia’s most active industrial regions. Many hazards cannot be fully eliminated through engineering controls alone, making personal protective equipment essential.

Using suitable coverall PPE in Johor helps to:

- Prevent direct skin contact with hazardous substances

- Reduce contamination of personal clothing

- Improve hygiene in controlled or sensitive environments

- Support workplace safety and compliance requirements

According to Malaysia’s Department of Occupational Safety and Health (DOSH), employers are responsible for identifying workplace hazards and ensuring appropriate protective measures are in place 👉DOSH

Common Industries Using Coverall PPE in Johor

Coverall PPE is widely used across multiple sectors, including:

Manufacturing and Production

Protection from dust, oils, residues, and mechanical exposure.

Construction and Maintenance

Shielding against cement dust, debris, and surface contaminants.

Chemical Handling and Industrial Cleaning

Reducing skin contact with liquids, vapours, and chemical splashes.

Logistics and Warehousing

Maintaining cleanliness and protection during material handling.

Each industry requires different protection levels, making correct coverall selection essential.

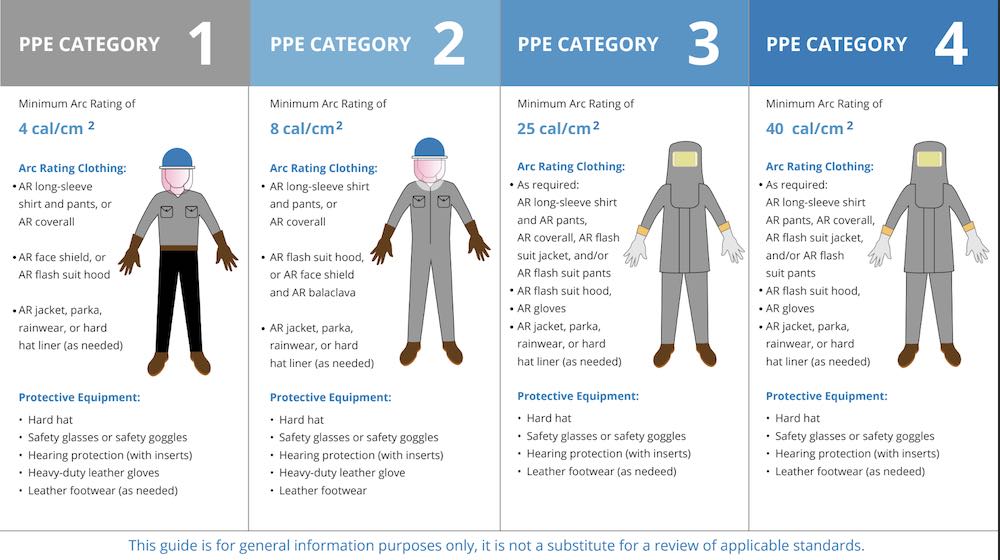

PPE Protection Levels Explained (Levels A, B, C, and D)

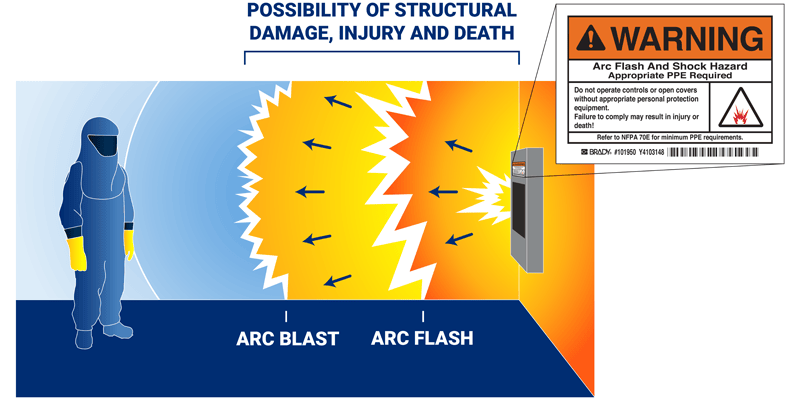

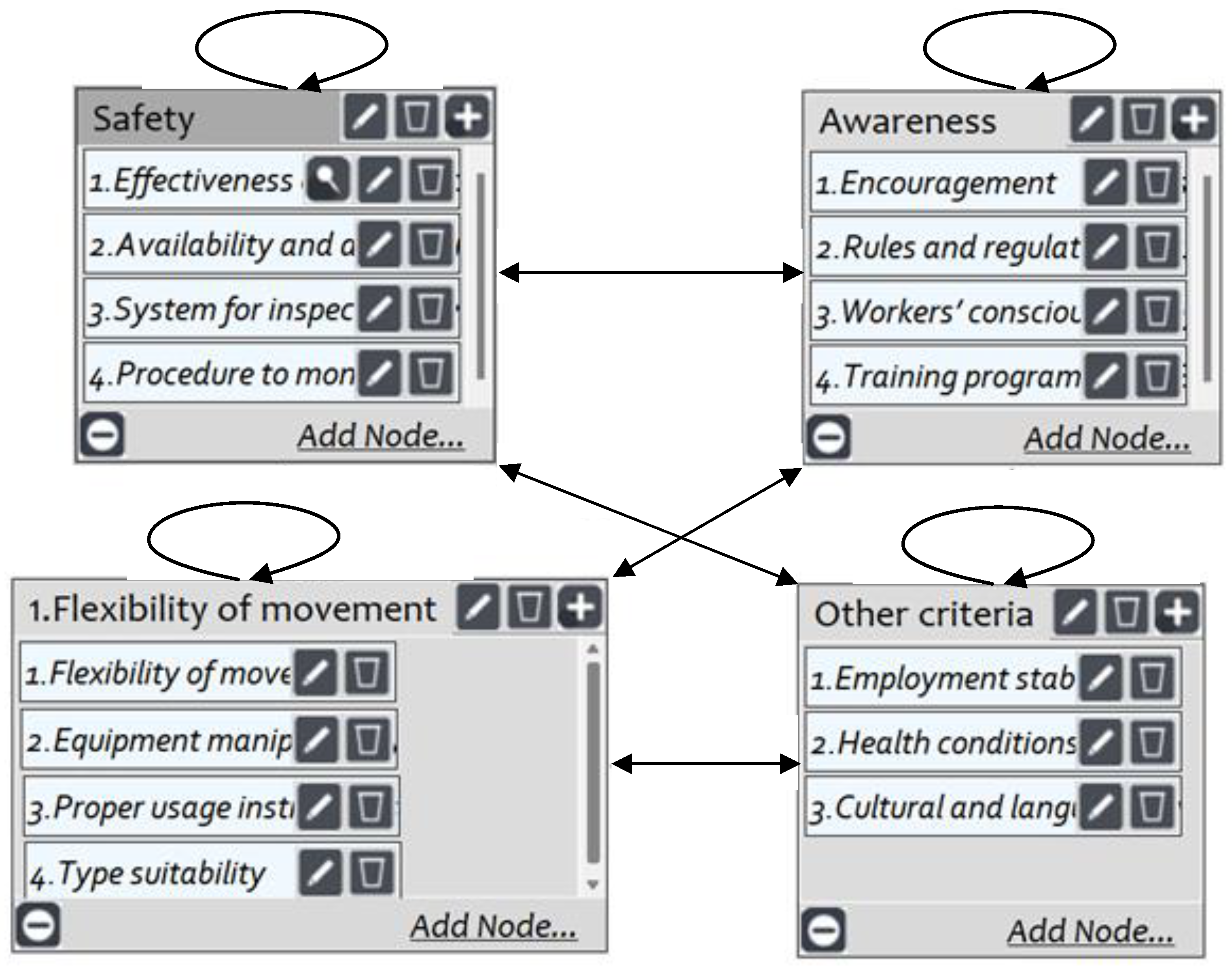

The image above illustrates the four recognised PPE protection levels, which help determine the correct type of coverall and respiratory protection based on hazard severity.

Level A – Maximum Protection

Level A provides the highest level of skin and respiratory protection. It includes a fully sealed chemical-resistant coverall and a self-contained breathing apparatus (SCBA). This level is used when exposure risks are extremely high or unknown, such as toxic chemical spills.

Level B – High Respiratory Protection

Level B offers maximum respiratory protection with slightly reduced skin protection compared to Level A. It includes protective coveralls and supplied-air or SCBA systems. This level is suitable when airborne hazards are severe but skin exposure is less critical.

Level C – Moderate Protection

Level C PPE is used when contaminants are known and can be filtered. It includes protective coveralls and air-purifying respirators. This level is common in industrial cleaning, maintenance work, and controlled chemical environments.

Level D – Basic Protection

Level D provides minimal protection and is suitable for low-risk environments. It includes basic coveralls, safety helmets, gloves, and simple face masks. Level D PPE is commonly used where no significant chemical or respiratory hazards are present.

This comparison highlights why matching coverall PPE to the correct protection level is essential for safety and comfort.

Types of Coverall PPE

Different work environments require different types of coveralls.

Disposable Coverall PPE

Lightweight and designed for single-use tasks involving dust or light contamination.

Reusable Industrial Coveralls

Durable coveralls suitable for repeated use in manufacturing and maintenance operations.

Chemical-Resistant Coveralls

Designed to protect against liquid splashes and chemical exposure.

Flame-Resistant Coveralls

Used in environments with heat or fire risks, such as welding operations.

These products are commonly part of industrial safety equipment supplied to Johor industries.

How to Choose the Right Coverall PPE in Johor

Selecting the right coverall PPE starts with understanding workplace risks.

Identify the Hazard

Determine whether workers are exposed to dust, chemicals, liquids, or heat.

Match Protection Level to Job Role

Avoid under-protection or unnecessary over-protection.

Consider Comfort and Climate

Johor’s hot and humid climate makes breathability and fit especially important.

Check Quality and Durability

High-quality coveralls provide consistent protection and longer service life.

For better comfort and branding, some workplaces also use customised workwear designed for specific operational needs.

Common Mistakes When Using Coverall PPE

One common mistake is choosing coveralls based only on price. Low-quality coveralls may tear easily or fail to protect adequately.

Another issue is incorrect sizing, which can restrict movement or leave exposed areas. Reusing disposable coveralls beyond their intended use also increases safety risks.

Proper selection, training, and replacement are essential.

Benefits of Using Proper Coverall PPE

When used correctly, coverall PPE provides:

- Improved worker safety and hygiene

- Reduced risk of skin contact and contamination

- Better compliance with safety practices

- Increased worker confidence and productivity

Reliable suppliers with a strong commitment to safety help ensure consistent quality and long-term protection.

Choosing a Reliable Coverall PPE Supplier in Johor

A trusted PPE supplier in Johor should offer:

- A wide range of coverall PPE options

- Products suitable for different protection levels

- Consistent availability and local support

- Practical guidance on selection and usage

Choosing the right supplier ensures your safety program remains effective over time.

Frequently Asked Questions (FAQs)

What is coverall PPE used for?

Coverall PPE protects the body from dust, chemicals, liquids, and workplace contaminants.

Are disposable coveralls suitable for industrial use?

Yes, for short-term or low-risk tasks. Higher-risk work may require reusable or chemical-resistant coveralls.

How often should PPE coveralls be replaced?

Disposable coveralls should be replaced after use. Reusable coveralls should be replaced when damaged or worn.

Is coverall PPE mandatory in Johor workplaces?

Requirements depend on the hazard level, but coveralls are widely used to support workplace safety.

Finding a reliable PPE supplier in Johor is not just about purchasing safety equipment - it is about protecting people, meeting safety requirements, and keeping operations running smoothly. In industrial regions such as Johor Bahru and Pasir Gudang, workplaces face daily risks that demand dependable personal protective equipment and consistent supply support.

A trusted PPE supplier plays a key role in workplace safety by ensuring the right equipment is available, compliant, and suitable for real working conditions.

What Does a PPE Supplier Do?

A PPE supplier provides personal protective equipment designed to protect workers from workplace hazards. This includes equipment for head, eye, hand, respiratory, body, and foot protection.

More importantly, a professional PPE supplier does more than sell products. They help organisations:

- Identify suitable PPE for specific hazards

- Ensure equipment meets safety standards

- Maintain consistent supply for ongoing operations

- Support long-term safety programs

In high-risk environments, choosing the right supplier can directly affect worker safety and compliance outcomes.

Why Choosing the Right PPE Supplier in Johor Matters

Johor is home to manufacturing plants, construction sites, logistics hubs, ports, and industrial parks. These environments expose workers to hazards such as heavy machinery, dust, chemicals, noise, and moving vehicles.

A reliable PPE supplier in Johor understands local industry needs and can provide:

- Equipment suited for hot and humid conditions

- Products aligned with Malaysian safety expectations

- Faster availability and local support

- Practical guidance based on real job-site conditions

Working with the wrong supplier often leads to inconsistent quality, delays, and safety gaps that put workers at risk.

Types of PPE Commonly Supplied in Johor

A complete PPE supplier typically offers a wide range of safety equipment to cover different workplace risks.

Head Protection

Head protection PPE is essential for preventing injuries caused by falling objects, overhead hazards, and accidental head impacts. Common equipment includes safety helmets and industrial hard hats, widely used in construction sites, factories, and maintenance work.

Quality head protection should be impact-resistant, comfortable, and suitable for long working hours. Reliable safety helmets help reduce serious head injuries and support safer job sites.

Eye Protection

Eye protection PPE shields workers from dust, flying debris, sparks, and chemical splashes. This includes safety goggles, protective eyewear, and face shields, commonly required in welding, laboratories, and industrial environments.

Using proper eye protection prevents vision damage and eye injuries that can occur instantly. A professional PPE supplier offers eye protection suitable for different industrial risks.

Hearing Protection

Hearing protection equipment is used to reduce exposure to high noise levels that can cause permanent hearing loss. Earplugs and earmuffs are commonly used in factories, workshops, and heavy machinery operations.

Consistent use of hearing protection supports long-term worker health and is an important part of industrial safety programs.

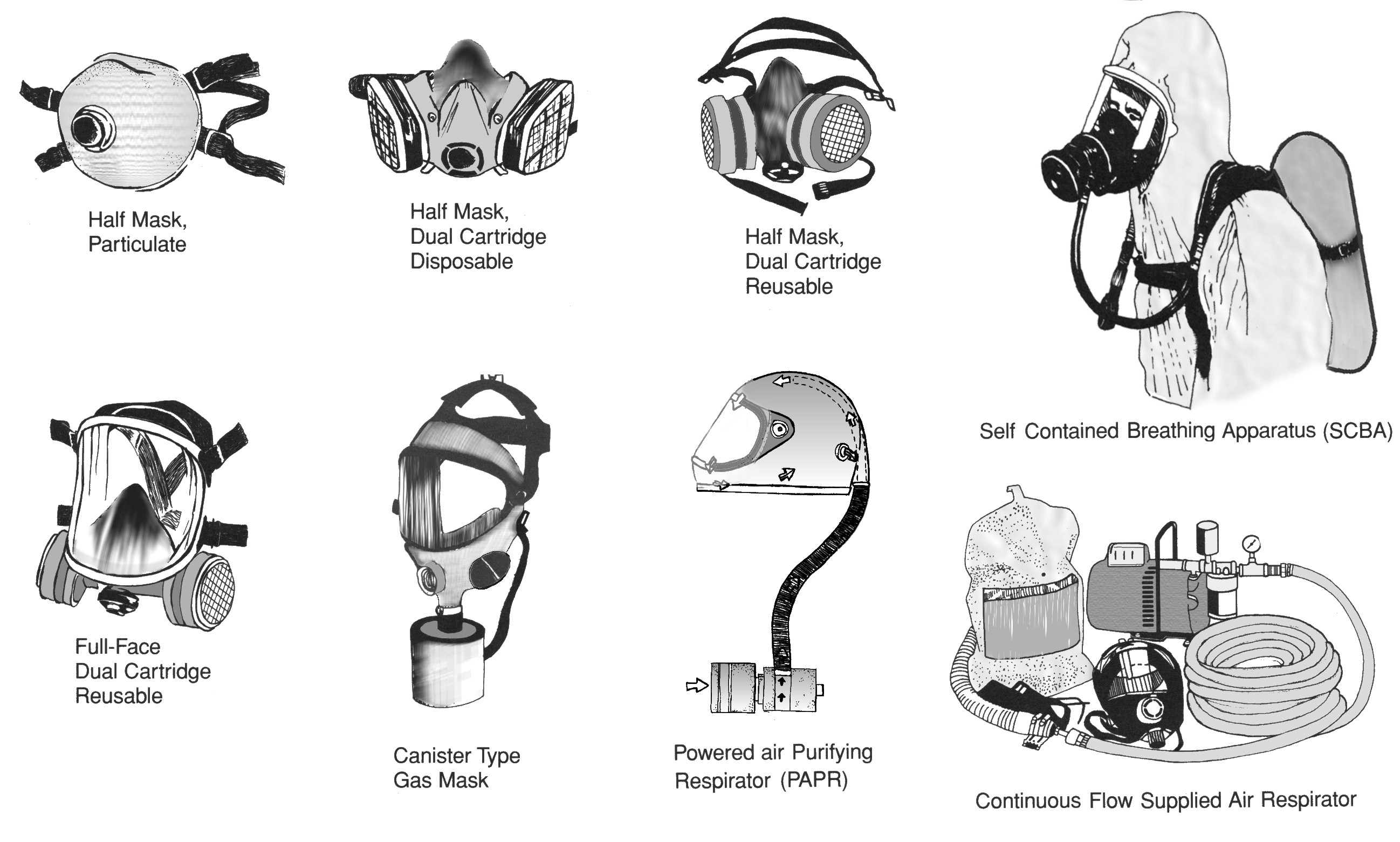

Respiratory Protection

Respiratory protection equipment protects workers from inhaling hazardous airborne substances such as dust, fumes, vapours, gases, and biological contaminants. This includes disposable masks, half-face respirators, full-face respirators, and powered air-purifying respirators (PAPR).

Respiratory protection is critical in construction, manufacturing, welding, and chemical handling environments. Proper selection and maintenance of respirators help reduce long-term respiratory health risks and support workplace safety compliance.

Hand Protection

Hand protection PPE helps prevent injuries from cuts, abrasions, chemicals, heat, and impact. Safety gloves are available in different materials depending on the task and hazard level.

Hands are among the most exposed parts of the body in industrial work, making proper glove selection essential for injury prevention and productivity.

Body Protection

Body protection PPE includes protective clothing, coveralls, and high-visibility safety vests, designed to protect workers from physical hazards and improve visibility in high-risk areas.

High-visibility clothing is especially important in construction, logistics, and roadwork environments. Certified high-visibility safety vests help ensure workers remain clearly visible and protected.

Foot Protection

Foot protection PPE protects workers from impact, slips, punctures, and heavy loads. Safety shoes and safety boots are commonly required in construction sites, warehouses, and industrial facilities.

Proper industrial footwear improves stability, reduces injury risk, and supports long working shifts in demanding environments.

Why Choosing a Reliable PPE Supplier Matters

Selecting PPE from a trusted supplier ensures product quality, consistent availability, and long-term safety support. Working with a supplier that demonstrates a strong commitment to safety helps organisations maintain effective workplace safety programs.

Key Qualities of a Trusted PPE Supplier in Johor

Not all PPE suppliers offer the same level of reliability. When evaluating a supplier, look beyond price alone.

Product Quality and Compliance

Equipment should be durable, reliable, and suitable for industrial use not consumer-grade alternatives.

Industry Knowledge

A good supplier understands different work environments and can recommend suitable PPE based on actual hazards.

Consistent Availability

Safety equipment should be available when needed, especially for ongoing projects and large workforces.

After-Sales Support

Guidance on usage, replacement, and maintenance adds long-term value beyond the initial purchase.

Common Mistakes When Choosing a PPE Supplier

One common mistake is selecting a supplier based only on cost. Cheaper equipment may wear out faster, fail to protect properly, or require frequent replacement.

Another issue is working with suppliers who lack industry knowledge. Without proper guidance, organisations may end up using incorrect or insufficient PPE for specific risks.

Lastly, inconsistent supply can disrupt operations and lead to unsafe workarounds when proper equipment is unavailable.

How to Choose the Right PPE Supplier for Your Business

Choosing the right PPE supplier starts with understanding your own workplace needs.

- Assess the hazards present in your operations

- Identify the PPE required for each job role

- Look for suppliers with experience in similar industries

- Prioritise reliability, support, and long-term partnership

A good PPE supplier becomes part of your safety system not just a vendor.

PPE Supply Across Johor Industries

In areas such as Johor Bahru, Pasir Gudang, and surrounding industrial zones, PPE suppliers support a wide range of sectors, including:

- Manufacturing and production facilities

- Construction and infrastructure projects

- Logistics and warehouse operations

- Maintenance and engineering services

Each industry has unique safety challenges, making supplier experience and flexibility especially important.

Benefits of Working with a Reliable PPE Supplier in Johor

When organisations work with the right supplier, they benefit from:

- Improved workplace safety

- Better compliance with safety expectations

- Reduced downtime and accidents

- Greater confidence among workers

- More efficient procurement and inventory planning

Strong PPE supply directly supports operational efficiency and worker well-being.

Frequently Asked Questions (FAQs)

What industries need PPE suppliers in Johor?

Manufacturing, construction, logistics, maintenance, and engineering industries commonly rely on PPE suppliers.

Is it better to use a local PPE supplier?

Yes. Local suppliers often provide faster support, better availability, and equipment suited to local working conditions.

Can one PPE supplier support multiple job roles?

A full-service supplier can provide PPE for different hazards and roles within the same organisation.

How often should PPE be replaced?

Replacement depends on usage, exposure, and manufacturer guidance. A good supplier can advise on replacement cycles.

Respiratory hazards are not always visible, but their impact can be serious and long-lasting. In many industrial environments, workers are exposed daily to dust, fumes, vapours, and airborne particles. This is why respiratory protection equipment in Johor has become an essential part of workplace safety across manufacturing, construction, logistics, and maintenance operations.

In industrial areas such as Johor Bahru, Pasir Gudang, and Iskandar Puteri, where factories, ports, and large-scale projects are concentrated, proper respiratory protection plays a critical role in protecting worker health and reducing operational risk.

What Is Respiratory Protection Equipment?

Respiratory protection equipment refers to personal protective equipment designed to protect the wearer from inhaling harmful substances in the air, including dust, chemical fumes, gases, vapours, and biological contaminants.

Think of respiratory protection like a filter for your lungs. Just as clean water needs a proper filtration system, clean air for workers requires the right mask or respirator.

As part of a complete PPE range, respiratory protection equipment works together with helmets, gloves, and protective clothing to create layered workplace protection.

Why Respiratory Protection Equipment Is Critical in Johor Industries

Johor is one of Malaysia’s most active industrial regions, home to manufacturing plants, construction projects, logistics hubs, and port operations. Many of these workplaces generate airborne hazards that cannot be fully eliminated through engineering controls alone.

Without proper respiratory protection:

- Fine dust can damage lung tissue over time

- Chemical vapours may cause dizziness or long-term illness

- Welding fumes increase chronic respiratory risks

According to Malaysia’s Department of Occupational Safety and Health (DOSH), employers are responsible for identifying workplace hazards and ensuring suitable protective measures are implemented.

Common Workplace Respiratory Hazards

This image shows how exposure to airborne hazards such as dust, fumes, smoke, chemicals, and biological particles can lead to common respiratory problems when proper protection is not used. It highlights the risk of breathing difficulties, lung damage, and long-term respiratory illness across industrial, emergency, and healthcare environments, emphasizing the importance of using suitable respiratory protection equipment to prevent these issues.

1. Dust and Particulates

Common in construction sites, cement handling, woodworking, and manufacturing facilities.

2. Fumes and Vapours

Often present during welding, spray painting, chemical processing, and cleaning tasks.

3. Gases and Chemical Exposure

Found in laboratories, industrial plants, and maintenance work involving solvents or fuels.

4. Biological Contaminants

Relevant in healthcare, waste management, and sanitation-related operations.

Types of Respiratory Protection Equipment

Illustration showing different types of respiratory protection equipment, including half masks, full-face respirators, powered air-purifying respirators (PAPR), and supplied-air breathing systems for industrial safety.

Respiratory protection equipment includes several options, depending on exposure level.

1. Disposable Masks

Suitable for low-risk environments with nuisance dust.

2. Half-Face Respirators

Cover the nose and mouth and use replaceable filters or cartridges.

2. Full-Face Respirators

Provide higher protection by covering the entire face and eyes.

3. Powered Air-Purifying Respirators (PAPR)

Provide filtered airflow for long-duration or high-heat work.

These products typically fall under industrial safety equipment used across construction, manufacturing, and logistics environments.

🔎 Quick Guide: Choosing Respiratory Protection Equipment

- Dust & particles → Disposable mask or particulate respirator

- Welding fumes → Half-face respirator with particulate filter

- Chemical vapours → Full-face respirator with gas cartridge

- Long-duration work → Powered air-purifying respirator (PAPR)

Common Johor Worksite Scenarios Requiring Respiratory Protection

Respiratory protection is commonly required in:

- Manufacturing plants in industrial parks

- Welding and fabrication workshops

- Port and logistics operations in Pasir Gudang

- Construction and renovation sites

In these settings, airborne risks can change quickly, making proper equipment selection essential.

How to Choose the Right Respiratory Protection Equipment in Johor

Assess the Airborne Hazard

Identify whether exposure comes from dust, fumes, vapours, or gases.

Match Protection Level to Exposure

Higher-risk work requires certified respirators and proper cartridges.

Consider Comfort and Fit

Poor fit reduces protection. Fit testing is essential for effectiveness.

Climate and Environmental Factors

Johor’s warm and humid conditions make comfort important. In some cases, customised workwear can improve usability and compliance.

Compliance and Employer Responsibilities

Under Malaysian occupational safety regulations, employers must ensure that respiratory hazards are identified and suitable PPE is provided, maintained, and used correctly.

This aligns with international guidance such as OSHA’s Respiratory Protection Standard, which highlights hazard assessment, fit testing, training, and maintenance as critical elements.

Benefits of Using Proper Respiratory Protection Equipment

When used correctly, respiratory protection equipment:

- Reduces short- and long-term health risks

- Supports regulatory compliance

- Improves productivity and confidence

- Reduces medical costs and downtime

Working with suppliers that demonstrate a strong safety commitment helps ensure long-term reliability and quality.

Frequently Asked Questions (FAQs)

What industries in Johor require respiratory protection equipment?

Manufacturing, construction, welding, logistics, chemical handling, and maintenance industries commonly require respiratory protection.

Are disposable masks enough for industrial work?

Only for low-risk dust exposure. Industrial fumes or chemicals require respirators with appropriate filters.

How often should respirator filters be replaced?

According to manufacturer guidelines or sooner if breathing becomes difficult.

Is fit testing necessary?

Yes. Fit testing ensures contaminated air does not bypass the respirator seal.

1. Introduction

A high visibility safety vest is one of the simplest yet most effective tools for preventing workplace accidents. In busy industrial and construction environments, high visibility safety vests help workers stand out before danger gets too close. When used correctly, they reduce risk, support compliance, and protect lives.

- What Are High Visibility Safety Vests?

A high visibility safety vest is a type of personal protective equipment designed to make the wearer clearly visible in both daylight and low-light conditions. These vests combine fluorescent colors for daytime visibility with reflective strips that shine when hit by artificial light.

You can think of them like road signs worn on the body. Just as a bright warning sign alerts drivers from a distance, a reflective safety vest alerts equipment operators and drivers that a person is present.

As part of a complete PPE range, high visibility safety vests are typically worn alongside helmets, gloves, and safety footwear to create layered protection in hazardous environments.

- Why High Visibility Safety Vests Are Critical for Workplace Safety

Many workplace accidents happen not because workers act unsafely, but because they are not seen in time. Forklifts reversing, trucks entering loading bays, or machinery operating in tight spaces all create visibility risks.

A hi vis safety vest works like a constant visual warning. It signals presence instantly, even from a distance. This is why high visibility vests are considered essential PPE in high-risk industries.

In fact, high visibility clothing is often listed alongside helmets and safety shoes as essential PPE for workplaces where people and moving equipment interact. When visibility improves, reaction time improves and accidents drop.

- Key Regulations and Safety Standards for High Visibility Vests

High visibility safety vests are not just recommended; in many cases, they are legally required.

4.1 International Standards (ISO, EN, ANSI/ISEA)

Globally, safety vests are governed by standards such as ANSI/ISEA and ISO 20471. These standards define minimum brightness levels, reflective tape placement, and performance after washing.

4.2 Industry-Specific Compliance Requirements

Construction, logistics, and road work often require higher-class vests due to faster-moving vehicles and greater exposure to risk.

4.3 Employer Responsibilities and Legal Implications

Employers are responsible for providing compliant PPE and replacing worn-out vests. Failure to do so can lead to fines, project shutdowns, or liability after accidents.

- Types of High Visibility Safety Vests by Use Case

High visibility safety vests are part of broader protective workwear, and different jobs require different designs.

5.1 Construction and Road Work Vests

Designed for high-speed traffic zones and heavy machinery environments.

5.2 Manufacturing and Warehouse Vests

Lightweight vests focused on forklift and pallet traffic visibility.

5.3 Logistics, Ports, and Transportation Vests

Built for wide-open areas, changing weather, and night operations.

5.4 Emergency and Night-Work Vests

Provide maximum reflectivity and 360-degree visibility.

- High Visibility Vest Classes Explained (ANSI/ISO)

Safety vest classes define how visible a worker must be based on risk level.

6.1 Class 1: Low-Risk Environments

For controlled areas with slow-moving equipment.

6.2 Class 2: Moderate Traffic and Industrial Areas

Common in construction sites and busy industrial zones.

6.3 Class 3: High-Risk and High-Speed Environments

| Vest Class | Risk Level | Typical Use |

|---|---|---|

| Class 1 | Low | Warehouses |

| Class 2 | Medium | Construction |

| Class 3 | High | Road & Night Work |

Required for highway work, night work, and high-speed traffic exposure.

Choosing the wrong class is like wearing a helmet that doesn’t fit it looks fine, but it won’t protect you when it matters.

- Materials and Design Features That Impact Performance (≈180 words)

Not all high visibility safety vests perform the same.

7.1 Fabric Types and Durability

Mesh offers breathability, while solid fabrics offer higher durability.

7.2 Reflective Tape Quality and Placement

Low-quality tape fades quickly and reduces compliance.

7.3 Breathability, Weight, and Comfort

Comfort directly affects whether workers wear vests correctly and consistently.

- How to Choose the Right High Visibility Safety Vest for Your Workforce (≈240 words)

Choosing the right vest starts with understanding the worksite.

8.1 Assessing Worksite Risks

Consider vehicle speed, lighting, and environment.

8.2 Matching Vest Class to Job Role

Different roles require different visibility levels.

8.3 Climate and Environmental Considerations

Hot climates may require mesh; outdoor work may need durability.

8.4 Sizing, Fit, and Compatibility with Other PPE

For unique needs or branding, customised workwear can improve comfort, compliance, and identification without reducing safety performance.

- Benefits of Using Certified High Visibility Safety Vests (≈150 words)

Certified vests reduce risk, simplify inspections, and support a strong safety culture. Working with suppliers that demonstrate a clear safety commitment also strengthens long-term compliance and trust.

Certified PPE is not just about passing audits it’s about protecting people consistently.

10. Common Mistakes Companies Make When Buying Safety Vests

One of the most common mistakes is choosing a high visibility safety vest based on price instead of performance. Low-cost vests often fade quickly or lose their reflective properties after repeated washing, which can lead to non-compliance.

Another mistake is using the same vest for every role. A warehouse worker and a road maintenance worker face very different risks. Using the wrong vest class can create a false sense of safety.

Some organisations also overlook fit and comfort. If a hi vis safety vest is too tight, too loose, or uncomfortable, workers may wear it incorrectly or not at all. Finally, many teams fail to plan for replacement, continuing to use worn or damaged vests long after they stop providing proper visibility.

- Best Practices for Bulk Purchasing and Inventory Management (≈180 words)

Buying high visibility safety vests in bulk can reduce costs, but only when done strategically.

11.1 Standardizing PPE Across Teams

Standardising vest types and classes across similar roles makes training easier and ensures consistent compliance. Workers know exactly what to wear and when.

11.2 Cost vs. Quality Considerations

Cheaper vests often need replacing sooner. A durable, certified reflective safety vest usually offers better long-term value, even if the upfront cost is slightly higher.

11.3 Replacement Cycles and Stock Planning

Plan replacement cycles based on usage, washing frequency, and exposure to sunlight and chemicals. Keeping a small buffer stock helps avoid shortages when damaged vests need immediate replacement.

- Maintenance, Inspection, and Replacement Guidelines (≈150 words)

Regular inspection is essential to ensure a high visibility safety vest continues to perform as intended. Check vests for fading fabric, torn seams, and peeling reflective tape.

Washing should follow manufacturer instructions. Harsh detergents and high heat can damage reflective materials, reducing visibility over time.

A simple rule works well: if the vest no longer stands out clearly under light, it should be replaced. Visibility that is “good enough” during the day may fail at night or in bad weather. Treat worn vests the same way you would treat damaged helmets or gloves replace them without delay.

- Frequently Asked Questions

13.1 What class of high visibility vest is required for construction sites?

Most construction sites require Class 2 or Class 3 high visibility safety vests, depending on traffic speed, equipment movement, and lighting conditions.

13.2 How often should high visibility vests be replaced?

There is no fixed timeline. Replace them when fabric fades, reflective tape loses brightness, or damage affects compliance.

13.3 Are reflective vests mandatory under workplace safety laws?

In many industries, yes especially where workers are exposed to vehicle or equipment movement. Requirements depend on local regulations and risk assessments.

13.4 What is the difference between ANSI and ISO standards?

ANSI standards are commonly used in North America, while ISO and EN standards are widely applied internationally. Both define visibility levels and performance requirements.

13.5 Can high visibility vests be customized with company logos?

Yes, as long as customization does not cover or reduce required reflective areas or affect compliance.

13.6 Do worn or faded vests still meet compliance requirements?

No. A vest that has lost visibility no longer meets safety standards, even if it is still structurally intact.

13.7 Are mesh vests suitable for heavy industrial environments?

Mesh vests are ideal for hot conditions but may not provide enough durability for all industrial settings. Always match vest type to worksite risk.

Workplace accidents cost businesses billions every year through downtime, compensation claims, legal penalties, and rising insurance premiums. In 2026, ignoring industrial safety products is no longer a manageable risk; it is a direct threat to business continuity and workforce safety. Companies that invest early in modern industrial safety products protect employees, strengthen compliance, and reduce long-term operational costs.

If your organisation is reviewing its safety strategy or preparing for stricter regulations, acting now is critical. By upgrading to certified, future-ready industrial safety products, businesses can prevent incidents before they occur and avoid costly disruptions. You can explore Haisar’s PPE and industrial safety product range to identify equipment designed for real-world industrial risks: 👉 Safety Products

As industrial environments become more complex, safety equipment must do more than meet minimum standards. This guide highlights the top 10 industrial safety products every business should prioritise in 2026 to maintain compliance, protect workers, and build a safer, more resilient operation.

Why Industrial Safety Products Are a Strategic Investment

Safety is no longer just a legal requirement, it is a business strategy. Companies that invest in high-quality industrial safety products experience fewer injuries, lower insurance premiums, stronger employee morale, and improved productivity. Many contracts and certifications now require documented safety systems and approved protective equipment.

Regulatory bodies such as OSHA and DOSH Malaysia continue to tighten enforcement, making prevention more cost-effective than reaction.

- Smart Hard Hats and Advanced Head Protection

Head injuries remain among the most severe workplace hazards. Smart hard hats are now essential industrial safety products across construction, manufacturing, and logistics. These helmets feature impact detection, fall alerts, and heat exposure monitoring, allowing faster emergency response.

To upgrade workplace PPE, businesses can view certified head protection and PPE solutions from Haisar: 👉 PPE solutions from Haisar

- Powered Air-Purifying Respirators (PAPR)

Respiratory hazards from dust, fumes, and chemicals are rising across industrial environments. Powered Air-Purifying Respirators are advanced industrial safety products that provide continuous filtered airflow and reduce worker fatigue.

For regulatory clarity, businesses should review OSHA’s respiratory protection standards before selecting respiratory equipment.

- Ergonomic and High-Visibility Safety Apparel

High-visibility and ergonomic workwear are foundational industrial safety products that reduce collision risks and physical strain. Modern designs improve comfort, encouraging consistent PPE usage in warehouses, ports, and construction zones.

Businesses can browse high-visibility and ergonomic PPE from Haisar to equip teams with compliant safety apparel:👉 High-Visibility Safety Apparel

- Self-Retracting Lifelines and Fall Protection Systems

Falls remain one of the leading causes of workplace fatalities. Self-retracting lifelines are critical industrial safety products that limit fall distance while allowing mobility at height.

Companies focused on compliance and prevention can learn more about Haisar’s safety philosophy and commitment: 👉Fall Protection Systems

- Portable and Temporary Anchoring Systems

Portable anchoring systems are flexible industrial safety products designed for dynamic worksites. They enable quick installation without permanent modifications, making them ideal for maintenance and temporary platforms.

- Proximity Sensors and Collision Avoidance Systems

Modern industrial safety products include proximity sensors that detect nearby workers and alert machine operators. These systems significantly reduce blind-spot incidents in logistics and manufacturing environments.

- Wearable Proximity Alert Devices

Wearable proximity devices add an additional protection layer. These industrial safety products alert workers when approaching hazardous zones, improving situational awareness in noisy or congested sites.

- Real-Time Gas Detection and Environmental Monitoring

Gas detectors are essential industrial safety products for identifying invisible hazards such as carbon monoxide and toxic vapours. Real-time alerts allow immediate corrective action before exposure becomes dangerous.

- Chemical-Resistant PPE and Spill Containment Systems

Chemical handling requires specialised industrial safety products such as chemical-resistant gloves, suits, and spill kits. These tools protect workers while preventing environmental contamination.

Businesses handling hazardous substances can explore chemical handling safety equipment from Haisar: 👉 Chemical-Resistant PPE

- Integrated Safety Management Platforms

Advanced industrial safety products now integrate with digital platforms that track PPE inspections, compliance status, and incident trends. These systems simplify audits and improve accountability.

To stay informed, organisations can read practical safety insights on the Haisar Blog:

👉 Safety Management Platforms

Take Action Before Risks Become Reality

In 2026, workplace safety must be predictive, data-driven, and proactive. Investing in modern industrial safety products protects employees, strengthens compliance, and supports long-term business sustainability.

If you are ready to upgrade your safety program, find your nearest Haisar office or request expert guidance:

👉 Take Action Before Risks Become Reality

Choosing the right safety products in Malaysia is one of the most important decisions any business can make. The quality of your PPE directly impacts worker safety, regulatory compliance, and project continuity. Yet, many companies still rely on uncertified or unsuitable equipment, often realizing the risks only after an incident occurs.

If you are responsible for sourcing certified PPE in Malaysia, this guide will help you avoid costly mistakes. You will learn how to select the right PPE, evaluate suppliers, and purchase industrial safety equipment that meets Malaysian standards.

For immediate assistance or a fast quotation, contact Haisar Supply & Services today and secure your PPE before your next project deadline. Our certified products ensure compliance, durability, and worker protection.

What Are Safety Products and Why They Matter in Malaysia

Safety products in Malaysia also known as Personal Protective Equipment (PPE) protect workers from hazards that could cause injury, illness, or long-term health issues. Industries like construction, manufacturing, oil and gas, and logistics rely on PPE not just for compliance but also for operational efficiency and workforce confidence.

High-quality safety products in Malaysia help:

- Reduce workplace accidents and injuries

- Ensure compliance with DOSH Malaysia regulations

- Boost workforce morale and confidence

- Prevent downtime due to accidents or safety violations

By choosing the right industrial safety equipment, companies can protect employees, reduce liability, and maintain productivity.

Common Types of Safety Products in Malaysian Worksites

Head Protection

Safety helmets and hard hats protect against falling objects, impact injuries, and electrical hazards. Essential for construction and industrial facilities. Browse Haisar helmets and head protection

Eye and Face Protection

Safety goggles, face shields, and welding masks safeguard workers from dust, sparks, chemicals, and debris.

Respiratory Protection

Masks and respirators protect workers from airborne particles, fumes, and hazardous substances. Using certified PPE in Malaysia ensures compliance with SIRIM standards.

Hand Protection

Industrial gloves protect against cuts, heat, chemicals, and abrasions. Choosing gloves suitable for your industry is critical.

Foot Protection

Safety shoes and boots protect against heavy objects, sharp debris, slips, and electrical risks.

Internal Link: Explore our safety footwear collection

Body Protection

Coveralls, flame-resistant clothing, and high-visibility vests provide full-body protection and visibility.

Fall Protection

Harnesses, lanyards, and lifelines are essential for working at heights, especially in construction and maintenance industries.

Infographic / Table: PPE vs Industries

|

PPE Type |

Const |

Manuf |

Oil & Gas |

Logis |

Data.C |

|

Helmets |

✅ |

❌ |

✅ |

❌ |

❌ |

|

Safety Shoes |

✅ |

✅ |

✅ |

✅ |

✅ |

|

Gloves |

✅ |

✅ |

✅ |

✅ |

❌ |

|

Eye Protection |

✅ |

✅ |

✅ |

❌ |

✅ |

|

Respiratory PPE |

❌ |

✅ |

✅ |

❌ |

✅ |

|

Fall Protection |

✅ |

❌ |

❌ |

❌ |

❌ |

|

High-Visibility Clothing |

✅ |

❌ |

✅ |

✅ |

❌ |

What Makes Quality Safety Products

Certifications and Standards

Ensure PPE complies with:

- SIRIM-certified PPE

- DOSH Malaysia requirements

- International standards (CE, ANSI, ISO)

Certified safety products in Malaysia provide peace of mind and guarantee real-world protection.

Durability and Materials

High-quality PPE lasts longer, performs better, and protects consistently. Inferior materials compromise safety and increase long-term costs.

Comfort and Fit

Comfortable PPE encourages consistent use. Quality industrial safety equipment allows mobility and prolonged wear without discomfort.

Industries That Rely on Safety Products in Malaysia

- Construction: Helmets, safety shoes, harnesses

- Manufacturing: Gloves, eye protection, respiratory PPE

- Oil & Gas: Flame-resistant clothing, gas masks

- Warehousing & Logistics: High-visibility vests, safety footwear

- Data Centres: Electrical safety PPE and footwear

Learn more about Haisar’s industry-specific PPE

Where to Buy Quality Safety Products in Malaysia

Trusted Local Suppliers

Benefits of buying from local suppliers:

- Certified PPE

- Immediate stock availability

- Faster delivery in Johor and Malaysia

- Technical guidance for choosing PPE

Haisar Supply & Services offers a wide range of PPE and compliance-ready safety solutions.

Online Marketplaces

Convenient but verify certification. Always ensure safety products in Malaysia meet legal standards.

Evaluating a Supplier

Choose suppliers that:

- Provide certification documentation

- Have industry experience

- Maintain consistent stock

- Support bulk orders

How to Choose the Right Safety Products

- Identify Workplace Hazards – falls, chemical exposure, electrical risk

- Match PPE to Risk – use certified PPE in Malaysia for each hazard

- Verify Compliance – SIRIM, DOSH, international standards

- Consult an Expert Supplier – Haisar Supply & Services

Buying Tips

- Always request certification

- Avoid uncertified imports

- Purchase based on environment, not price

- Standardize PPE for all teams

- Plan ahead for bulk procurement

Callout Box (Expert Tip)

Expert Tip: Always confirm that PPE is SIRIM and DOSH certified before purchase. Using uncertified products can result in fines, accidents, or downtime.

FAQs

What safety products are required in Malaysia?

Helmets, gloves, safety shoes, eye protection, high-visibility clothing, and specialized PPE depending on the industry.

How can I verify PPE certification?

Look for SIRIM, DOSH, or international compliance marks. Learn more about SIRIM safety standards.

Is it better to buy locally?

Yes. Local suppliers provide faster delivery, better support, and compliance assurance.

Can SMEs buy PPE in bulk?

Yes. Many suppliers of safety products in Malaysia offer bulk pricing and project-based procurement options.

Conclusion

Investing in certified safety products in Malaysia protects your workforce, ensures compliance, and maintains productivity. Choosing high-quality PPE and working with trusted local suppliers like Haisar Supply & Services ensures your team stays safe.

Request a quotation today and secure your certified PPE in Johor don’t risk delays or non-compliance on your next project.

1. Why finding a reliable safety shoes supplier in Johor matters

In Johor, projects move fast. When schedules tighten, small problems become expensive problems especially when they involve safety. Safety shoes are not “just footwear.” They are PPE that protects your people from slips, sharp objects, heavy drops, and site conditions that change by the hour.

A reliable safety shoes supplier helps you do two things at once: reduce injury risk and keep work moving. The right supplier also saves you from last-minute “size-not-available” panic, inconsistent models, and paperwork that does not stand up to audits.

This guide walks you through what to look for both in the shoes and in the supplier so you can buy once, standardize well, and avoid repeat issues.

1.1 Who this guide is for

If you are responsible for safety footwear decisions whether for a small crew or multiple sites this is for you. You already know the basics of PPE and compliance. What you usually need is practical clarity:

- Which safety ratings match which hazards

- Which shoe types work for Johor’s common site conditions

- How to buy for teams without sizing chaos

- How to compare suppliers beyond “cheapest price”

Think of this as a field guide: short explanations, clear checklists, and buying steps you can apply immediately.

1.2 Common buying mistakes in Johor projects

Most problems come from a few repeat mistakes:

Mistake 1: Buying by price only. A cheaper pair that fails early (or causes discomfort) can cost more through replacements, downtime, and complaints.

Mistake 2: Not matching hazards to the rating. Many teams buy “any safety shoe,” then discover it is wrong for wet floors, sharp debris, or outdoor work.

Mistake 3: No sizing plan. Bulk buying without fit trials leads to exchanges, delays, and wasted stock.

Mistake 4: Mixing too many models. When everyone wears a different shoe, reorders become messy and inconsistent.

Mistake 5: Weak documentation. If the supplier cannot provide clear compliance info, it creates audit headaches later.

- What a safety shoes supplier does

A good safety shoes supplier is more than a store that sells boots. In practice, the supplier should help you:

- Translate hazards into specifications (rating, outsole type, toe cap, midsole protection, water resistance)

- Offer the right categories and sizes consistently (so you can standardize)

- Support bulk purchasing (fit trials, exchanges, reorder planning)

- Deliver fast and reliably across Johor locations

- Back the product with warranty guidance and after-sales support

- Provide documentation you can keep for safety files and procurement records

If you want a quick starting point for available options, browse the Feet Protection category to see typical safety footwear ranges and types.

- Key industries in Johor that need safety shoes

Johor’s economy is built on active worksites each with different “foot risks.” The right supplier understands these environments and can recommend models that match them.

3.1 Construction and infrastructure

Construction sites often combine: uneven ground, wet patches, sharp debris, and heavy tools. Shoes usually need strong grip, toe protection, and puncture resistance, plus ankle support if the ground is rough.

3.2 Manufacturing and factories

Factories can involve: smooth floors, oil exposure, machine edges, and long standing hours. Comfort matters here because fatigue leads to mistakes. You typically need slip resistance, durable uppers, and good cushioning.

3.3 Warehousing and logistics

Warehouses involve: fast movement, pallet handling, and repetitive walking. Footwear needs to feel light but still protect from falling loads and slippery zones especially near loading bays.

For deeper role-by-role guidance, you can link readers to a supporting reference like By Industry.

- Benefits of buying from a local Johor supplier

Buying locally is not only about convenience. It reduces operational risk.

4.1 Faster delivery and stock availability

Local supply means fewer “waiting days” when something runs out. If a site expands headcount, you can restock faster. This matters because safety shoes are not optional if you cannot issue proper footwear, work slows down or stops.

A local supplier also tends to understand which sizes move fastest and can keep practical stock levels, not just “display items.”

4.2 On-site sizing and fitting support

Sizing is where bulk orders succeed or fail. Two people can wear the same size number but need different width or fit style. A supplier that supports fit trials helps you avoid a painful cycle of returns.

A good approach is simple:

- Run a short sizing session for each crew group

- Test 1–2 approved models

- Confirm comfort after a few hours of wear

It is like choosing a helmet: it must fit properly, or it becomes a problem instead of protection.

4.3 Easy warranty and replacement process

Footwear is used hard. If a sole separates, stitching tears, or defects appear early, you want a clean process: clear warranty terms, quick assessment, and fast replacement.

Local support usually means you can resolve issues without long shipping delays or back-and-forth arguments. This reduces friction for both procurement and site supervisors.

4.4 Better support for urgent site needs

When a project timeline shifts, you may need extra pairs immediately—especially common sizes. A nearby supplier can often support urgent top-ups and help you avoid site delays.

- How to choose the right safety shoes for your work

Selecting safety shoes is like selecting a tool: you match the tool to the job. Below is a simple, repeatable method.

If you want an additional reference for features and selection tips, link to a broader guide such as Safety Shoes Guide.

5.1 Step 1: Match shoes to site hazards

Start with hazards, not brands. Ask:

- Are floors often wet or oily?

- Is there sharp debris like nails, metal scraps, or rebar?

- Do workers face heavy drops or rolling objects?

- Is work mostly outdoor or indoor?

- Are there hot surfaces, welding sparks, or heat exposure?

Then translate hazards into features:

- Wet/oily floors → high slip resistance, suitable outsole compound

- Sharp debris → puncture-resistant midsole

- Heavy drops → toe protection and strong upper

- Outdoor works → durable build and water resistance

- Hot work → heat-resistant outsole when required

A practical tip: walk the site. If your shoes slip during a quick check, your team will slip during a long shift.

5.2 Step 2: Choose the right safety rating (S1, S1P, S2, S3)

Safety ratings help you standardize. In simple terms:

- S1: Basic protection (often includes toe protection and anti-static features) for drier indoor environments.

- S1P: S1 + puncture resistance (useful for sites with sharp debris).

- S2: Adds water resistance (often better for wet conditions, depending on design).

- S3: Stronger all-round choice for many sites—commonly includes toe protection, puncture resistance, and better outsole properties.

Think of ratings like vehicle categories: a sedan can handle city roads, but you do not send it into a muddy construction zone when you need a 4x4.

5.3 Step 3: Pick toe protection (steel vs composite)

Toe protection is often non-negotiable.

- Steel toe: Classic choice, strong and widely used.

- Composite toe: Lighter and does not conduct electricity the same way steel can; often preferred when weight and comfort are priorities.

Selection is usually about site needs and comfort expectations, not “which is better.” If workers complain about weight and fatigue, composite toe options can reduce resistance to wearing the shoes properly.

5.4 Step 4: Check outsole needs (slip, oil, heat)

Outsoles are your “tire grip.” If the outsole fails, the shoe fails.

Key checks:

- Slip resistance for smooth floors, rain, and oily zones

- Oil resistance for workshops and industrial areas

- Heat resistance for hot work conditions (when applicable)

- Tread pattern that suits the environment (deep tread for rough ground; stable tread for smooth surfaces)

A simple analogy: you would not use racing tires on a muddy road. Same idea.

5.5 Step 5: Prioritize comfort for long shifts

Comfort is not a luxury comfort is compliance. If shoes are painful, workers will loosen laces, swap footwear, or stop wearing them properly.

Look for:

- Good cushioning and support

- Breathable materials for humid days

- Correct sizing and width options

- Weight that suits long walking/standing roles

A good supplier helps you test fit and choose models that people will actually wear.

- Types of safety shoes commonly supplied in Johor

Most suppliers in Johor offer these practical categories. Choosing the right type helps you standardize and simplify reorders.

6.1 Low cut safety shoes

Best for many indoor roles: factories, warehouses, and logistics. Low cut shoes often feel lighter and allow easier movement. They are useful when:

- The ground is mostly even

- The job involves lots of walking

- Ankle support is not the main concern

They can still include toe protection and puncture resistance, depending on model and rating.

6.2 Mid cut safety shoes

Mid cut options balance flexibility and ankle support. They often fit mixed environments some indoor work, some outdoor walking. Mid cut is popular when:

- Floors vary (smooth inside, rough outside)

- Work includes carrying loads and climbing

- You want added ankle stability without “heavy boot” fatigue

6.3 High cut safety boots

High cut boots are common for heavy-duty and outdoor work. They provide stronger ankle support and often pair well with rough terrain. They suit:

- Construction and infrastructure sites

- Outdoor maintenance work

- Wet or uneven ground conditions

High cut does not automatically mean “better,” but it often means “more support” for challenging ground.

6.4 Waterproof and outdoor safety boots

For outdoor sites during rainy periods, waterproof boots reduce discomfort and skin issues caused by constant wet socks. Look for:

- Water-resistant uppers

- Sealed seams (when available)

- Outsole grip designed for wet ground

Be realistic: “water resistant” is not always “fully waterproof.” A good supplier should explain the difference clearly.

6.5 ESD and anti-static safety shoes

These are important in environments with sensitive electronics or where static control matters.

- Anti-static helps reduce static build-up in general environments.

- ESD footwear is designed for more controlled static discharge conditions.

If you see searches like “ESD safety shoes Johor” or “anti-static safety shoes Malaysia,” it usually signals controlled work areas or electronics-related processes.

- What to check before you buy (quality checklist)

Before you commit especially for bulk purchases use this checklist. It reduces surprises after delivery.

7.1 Certification and compliance labels

Ask for clear, consistent information:

- Safety rating (S1/S1P/S2/S3)

- Slip resistance markings (where applicable)

- Any ESD/anti-static identification

- Product documentation that matches the model delivered

A practical rule: if the supplier cannot explain the rating simply, treat it as a red flag.

7.2 Material quality and stitching

Look at the shoe like you would look at a safety harness details matter:

- Clean stitching without gaps

- Strong bonding between upper and sole

- Durable toe area protection

- Material that matches the environment (e.g., tougher uppers for rough sites)

7.3 Midsole puncture protection (steel vs fabric)

If your site has nails, sharp metal, or debris, puncture resistance matters.

- Steel midsole: traditionally strong; can add weight.

- Fabric/kevlar-type midsole: lighter; can improve comfort, depending on design.

Either can work if it matches the hazard profile and the shoe rating.

7.4 Grip test: outsole pattern and compound

Do a simple, practical check:

- Press the outsole; it should not feel overly hard and slippery

- Look at tread pattern; does it fit your floor type?

- Consider where the job happens (oil, rain, smooth epoxy floors)

It is like checking a ladder’s feet: if the base slips, the rest does not matter.

7.5 Size accuracy and fitting policy

For bulk orders, confirm:

- Size chart consistency across models

- Exchange process (time window, conditions)

- Whether the supplier supports fit trials

- How they handle odd sizes and special requests

A supplier with a clear exchange process saves you time and reduces friction with site teams.

- How to compare suppliers in Johor

Supplier comparison should be more than “who is cheapest.” Use a balanced scorecard: range, reliability, support, and speed.

8.1 Stock range and brand options

A good supplier can offer:

- Low/mid/high cut options

- Common safety ratings

- Multiple fit styles (to suit different feet)

- Continuity for repeat orders (same model availability)

A wide range matters because one shoe does not fit every job role.

8.2 Pricing: contract vs retail

Ask for clarity:

- Retail vs bulk pricing tiers

- Contract pricing for repeat orders

- What is included (delivery, exchange support, documentation)

Sometimes the best deal is not the lowest unit price—it is the lowest total friction.

8.3 Delivery coverage (JB, Kulai, Pasir Gudang, Pontian, etc.)

Delivery is where plans succeed or fail. Confirm:

- Delivery cut-off times

- Typical lead times by location

- Options for urgent restocks

- Packaging and labeling (helpful for distribution to crews)

8.4 After-sales support and returns

Support matters after the invoice is paid. Check:

- Warranty handling

- Exchange process

- Responsiveness to issues

- Clear communication (no guessing games)

8.5 Ability to handle bulk orders

Bulk capability is a real difference-maker. Ask if they can:

- Support fit trials

- Consolidate sizes and labeling

- Provide reorder support

- Keep steady stock for your approved models

If you want supporting context for evaluating broader PPE supply reliability, a relevant internal reference is PPE Supplier.

- How to buy safety shoes for a team (bulk purchase guide)

Bulk buying can be smooth or painful. Here is a process that keeps it smooth.

9.1 Step 1: Collect job roles and hazard profiles

Group people by work type:

- Heavy site work (construction/outdoor)

- Indoor production/factory work

- Warehouse/logistics

- Mixed role supervisors

Then match each group to hazard needs. This helps you avoid buying one “average” shoe that fits no one.

9.2 Step 2: Run a sizing day and fitting trial

Do a short fitting session:

- Confirm size and width

- Let workers walk and bend

- If possible, trial for a few hours

This reduces exchange rates and complaints. It also shows you respect comfort and compliance both matter.

9.3 Step 3: Standardize 2–3 approved models

Aim for a short approved list:

- Model A for heavy outdoor work

- Model B for indoor production

- Model C for warehouse/light duty (optional)

This makes reorders simple. It also helps with consistent appearance and predictable budgeting.

9.4 Step 4: Plan for spares and replacements

Plan spares like you plan spare helmets:

- Keep a buffer of common sizes

- Set a replacement rule (e.g., heavy wear roles replace earlier)

- Track issues (sole wear, toe damage, upper tears)

9.5 Step 5: Set a reorder system

Set a simple system:

- Who approves reorders

- Minimum stock level by size

- Monthly or quarterly review

- Preferred delivery schedule

This turns footwear into a controlled supply chain item, not a last-minute scramble.

- Delivery, lead times, and service expectations in Johor

Delivery is part of safety performance. If footwear arrives late, compliance suffers.

10.1 Same-day vs next-day delivery scenarios

Same-day delivery may work when:

- The supplier has local stock

- The sizes are common

- The request is placed early

Next-day is more realistic for:

- Larger quantities

- Multiple site locations

- Mixed sizes and models

Clarify cut-off time. A “fast supplier” is one that gives clear timelines, not vague promises.

10.2 Typical lead times for special sizes

Special sizes or less common models may require extra time. Plan ahead for:

- Very small or very large sizes

- Extra wide fits

- Specialty footwear (ESD-specific, certain materials)

If you standardize models early, lead times become predictable.

10.3 How to avoid project delays

Three simple habits prevent delays:

- Keep a buffer stock for common sizes

- Standardize models and document specs

- Reorder before stock hits zero (set a minimum level)

If you treat safety shoes like critical spare parts, downtime drops.

- Care and maintenance to extend shoe lifespan

Safety shoes last longer when teams care for them properly simple habits make a big difference.

11.1 Daily cleaning routine

A quick routine:

- Brush off debris

- Wipe with a damp cloth

- Clean soles to maintain grip

- Check for cuts, loose stitching, and sole separation

Five minutes a day can prevent early failure.

11.2 Drying and storage

Dry shoes properly:

- Do not leave them soaked in a corner

- Avoid direct extreme heat that can damage materials

- Use a ventilated space

- Rotate pairs when possible in heavy wet work

11.3 When to replace safety shoes

Replace when you see:

- Worn-out grip (slip risk increases)

- Sole separation

- Toe cap exposure

- Deep cracks or tears

- Loss of cushioning causing pain and fatigue

A worn outsole is like a bald tire. It might still “work,” but it is no longer safe.

11.4 Common damage causes and how to prevent them

Common causes: dragging toes, chemical exposure, poor drying, and using the wrong shoe for the job. Prevention is mostly matching the right type to the environment and keeping basic care habits.

- Price guide: what affects safety shoe cost in Johor

Prices vary, and the reasons are usually predictable.

12.1 Safety rating and materials

Higher ratings and stronger materials often cost more because they add:

- Better midsoles

- Stronger uppers

- More durable outsoles

- More protective components

12.2 Comfort features and weight

Lightweight shoes, better cushioning, and breathable designs may cost more. But they can reduce complaints and improve wear compliance often worth it for long shifts.

12.3 Brand, warranty, and support

Reliable warranty handling and consistent stock come with cost. What you are really paying for is reduced risk: fewer failures, fewer delays, and fewer disputes.

12.4 Bulk discount expectations

Bulk discounts often depend on:

- Quantity per model

- Standardized sizes

- Repeat ordering

- Contract terms

The best savings usually come from standardization, not from negotiating one-time discounts.

- Frequently asked questions (FAQ)

13.1 Which rating is best for construction sites?

For many construction environments, S1P or S3 is often a practical starting point because puncture resistance matters when sharp debris is common. If the site is frequently wet or muddy, choose options that handle water exposure better and provide strong grip. Always match the rating to real hazards, not assumptions.

13.2 Steel toe vs composite: which is better?

Neither is “always better.” Steel toe is widely used and strong. A composite toe is often lighter and can feel more comfortable for long shifts. Choose based on work conditions, comfort needs, and whether weight reduction improves compliance for your team.

13.3 How do I know if shoes are genuine and compliant?

Ask for clear product identification and documentation that matches the exact model delivered. Check rating markings and consistency across cartons, labels, and product information. A reliable supplier can explain the rating and provide supporting details without hesitation.

13.4 Do you provide size exchange for bulk orders?

A good bulk process includes an exchange plan. Confirm the exchange window, the condition requirements, and whether the supplier supports fit trials before the full order. Fit trials reduce exchanges dramatically and keep the rollout smooth.

13.5 How fast can you deliver in Johor?

Delivery speed depends on stock, order size, and location. Many suppliers can deliver quickly for common sizes if the order is placed early and stock is available. For mixed sizes or larger quantities, next-day delivery is more realistic. Always confirm cut-off time and delivery coverage.

13.6 What is ESD and who needs it?

ESD footwear helps control static discharge in sensitive environments, especially where electronics, components, or static-sensitive processes are involved. If your workplace has ESD zones or static control requirements, ESD footwear is often part of the overall control plan. If not, standard anti-static footwear may be sufficient depending on the site policy.

- Conclusion: quick checklist + next steps

Choosing a safety shoes supplier in Johor is not only about buying boots. It is about building a reliable supply line that keeps teams protected and projects moving.

14.1 5-point buying checklist recap

Use this quick checklist before you commit:

- Hazard match: shoe features match site risks (slip, puncture, wet, heat)

- Correct rating: S1/S1P/S2/S3 chosen with clear reasoning

- Fit plan: sizing day or fit trial before full bulk order

- Supplier readiness: stock continuity, delivery coverage, clear timelines

- After-sales clarity: warranty and exchange process is simple and written

If you follow these five points, you reduce the most common causes of delays, complaints, and non-compliance.

14.2 request quote / site support