Working with electricity, especially in places like Johor, comes with risks. One of the big ones is something called an arc flash. It's basically a super-intense burst of energy that can happen during an electrical fault. Think of it like a mini-explosion, but with electricity. This can cause serious burns and injuries if you're not prepared. That's why knowing about these hazards and having the right gear, like protective gloves, is so important for anyone working with electrical systems.

Key Takeaways

- Arc flashes are powerful electrical explosions that pose significant dangers, including severe burns and injuries.

- Understanding incident energy levels and maintaining a safe distance from electrical equipment is vital for protection.

- Personal Protective Equipment (PPE), especially flame-resistant clothing and insulated gloves, is mandatory for electrical work.

- Arc Thermal Performance Value (ATPV) ratings help determine the level of protection offered by PPE against arc flashes.

- Regular training, proper equipment maintenance, and adherence to safety standards like NFPA 70E are critical for workplace electrical safety.

Understanding Arc Flash Hazards in Johor

Working with electricity, especially in industrial settings here in Johor, comes with risks. One of the most serious is the arc flash. It's not just a small spark; it's a powerful electrical explosion that can happen when electricity jumps across an air gap. Think of it like a lightning strike happening right in front of you, but contained within electrical equipment. This event releases a tremendous amount of energy very quickly.

Defining Arc Flash and Its Dangers

So, what exactly is an arc flash? It's a type of electrical explosion or discharge that happens when current flows through an unintended path, like through the air. This can occur due to equipment failure, accidental contact, or even dust and moisture buildup. The dangers are significant. An arc flash produces intense heat, often reaching temperatures hotter than the surface of the sun. This heat can instantly vaporize metal, causing severe burns to anyone nearby. Beyond the heat, there's also a dangerous pressure wave, known as an arc blast, which can throw objects and people across a room. The noise alone can cause hearing damage. The primary risks include severe burns, blindness, hearing loss, and even death.

Incident Energy Levels and Proximity

The severity of an arc flash incident is measured by its incident energy, typically expressed in calories per square centimeter (cal/cm²). This value tells us how much thermal energy is released at a specific distance from the arc source. A key point to remember is that the closer you are to the arc, the higher the incident energy you'll experience. For instance, measurements are often taken at 18 inches, but if you're working closer than that, the energy level can be considerably higher. This means that even if your protective gear is rated for a certain distance, being closer can expose you to much greater danger. Understanding these energy levels is vital for selecting the right protective equipment.

Legal and Regulatory Frameworks (NFPA 70E, OSHA)

In Malaysia, as in many parts of the world, electrical safety is governed by regulations and standards designed to protect workers. While specific Malaysian standards exist, international frameworks like NFPA 70E (Standard for Electrical Safety in the Workplace) and OSHA (Occupational Safety and Health Administration) guidelines are often referenced and followed. These standards provide a roadmap for identifying hazards, assessing risks, and implementing safety measures. They outline requirements for things like hazard analysis, equipment labeling, and the use of appropriate personal protective equipment (PPE). Adhering to these frameworks is not just about compliance; it's about preventing serious injuries and fatalities. You can find more information on electrical safety assessments through arc flash assessments.

The goal of these regulations is to create an electrically safe work environment whenever possible. When working on energized equipment is unavoidable, strict protocols must be followed to minimize exposure to hazards like arc flash.

Essential Personal Protective Equipment (PPE)

When you're dealing with electricity, especially in Johor where industrial work is common, having the right gear is non-negotiable. This isn't just about comfort; it's about staying safe when things go wrong. We're talking about Personal Protective Equipment, or PPE for short. Think of it as your first line of defense against arc flash events.

Arc Flash PPE Categories and Selection

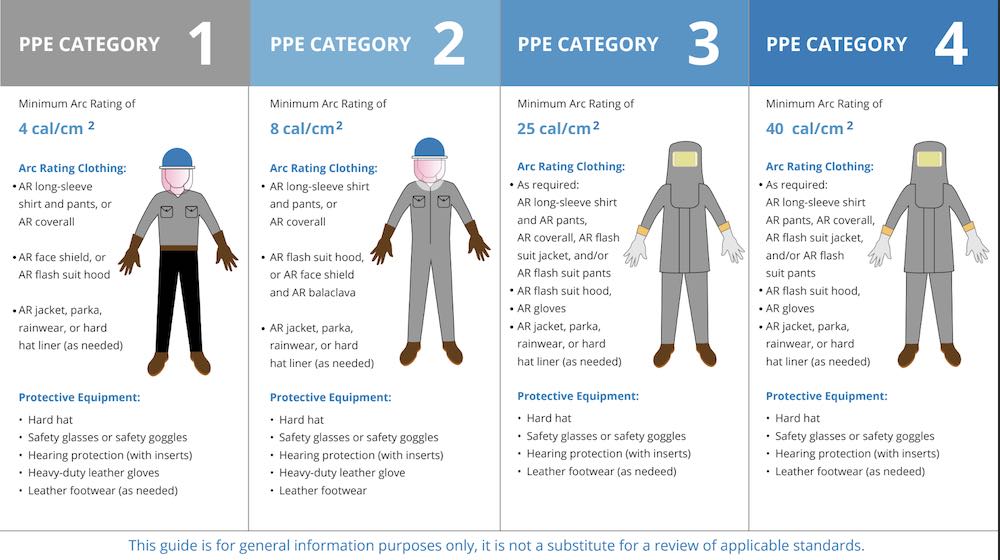

Not all PPE is created equal, and you can't just grab anything. The National Fire Protection Association (NFPA) has laid out categories for arc flash PPE. These categories help you figure out what level of protection you need based on the specific electrical hazard you're facing. It's all about matching the gear to the risk. The closer you are to the potential arc source, the more protection you'll need. For instance, working 18 inches away might require a different setup than working right next to the equipment.

Here's a general idea of how it works:

- Category 0: Minimal risk, often requires standard work clothes that are flame-resistant.

- Category 1: Requires clothing with an Arc Thermal Performance Value (ATPV) of at least 4 cal/cm².

- Category 2: Requires clothing with an ATPV of at least 8 cal/cm².

- Category 3: Requires clothing with an ATPV of at least 25 cal/cm².

- Category 4: Requires clothing with an ATPV of at least 40 cal/cm².

Importance of Flame-Resistant (FR) Clothing

Flame-resistant (FR) clothing is a big deal. It's designed to self-extinguish and not melt when exposed to flames or high heat. This is different from regular clothing, which can stick to your skin and make burns much worse. When an arc flash happens, the intense heat can ignite clothing. FR clothing acts as a barrier, giving you a better chance to get away from the hazard without severe burns.

The key is that FR clothing doesn't burn like normal fabrics. It's made from materials that have been treated or are inherently flame-resistant. This means it won't continue to burn once the heat source is removed, which is a critical difference in a flashover situation.

Understanding Arc Thermal Performance Value (ATPV)

So, what exactly is ATPV? It stands for Arc Thermal Performance Value, and it's measured in calories per square centimeter (cal/cm²). This rating tells you how much heat energy a piece of fabric can withstand before it breaks open and allows heat to pass through to the wearer. A higher ATPV rating means better protection against arc flash heat. When selecting PPE, you'll look at the calculated incident energy level for the task and choose clothing with an ATPV rating that meets or exceeds that level. It’s a scientific way to quantify how well a garment will protect you from the intense heat of an arc flash.

Protective Gloves for Electrical Safety

When you're dealing with electricity, especially in Johor where industrial work is common, your hands are often the closest point of contact with potential hazards. That's where insulated gloves come into play. They're not just any gloves; they're specifically designed to keep electricity from traveling through them and into your body. Choosing the right pair is absolutely critical for preventing serious injury or worse.

Types of Insulated Gloves

Insulated gloves are rated based on the voltage they can protect against. You'll see different classes, from Class 00 for low voltage up to Class 4 for very high voltage work. It's not a one-size-fits-all situation. You need to match the glove's rating to the voltage you'll be working with. They're typically made from rubber or a similar polymer that acts as an electrical insulator. Think of them as your first line of defense for your hands.

Here's a quick look at the common classes:

- Class 00: Up to 500 volts AC / 1,000 volts DC

- Class 0: Up to 1,000 volts AC / 1,500 volts DC

- Class 1: Up to 7,500 volts AC / 10,000 volts DC

- Class 2: Up to 17,000 volts AC / 20,000 volts DC

- Class 3: Up to 26,500 volts AC / 30,000 volts DC

- Class 4: Up to 36,000 volts AC / 40,000 volts DC

Leather Protectors and Their Role

Now, those rubber insulated gloves are great for protection, but they can get damaged pretty easily. That's where leather protector gloves come in. You wear these over your insulated gloves. They don't provide electrical protection themselves, but they shield the rubber gloves from cuts, punctures, and abrasions. This keeps the rubber in good condition, which is key to maintaining its insulating properties. Think of them as a tough outer shell for your primary safety gear.

Proper Inspection and Maintenance of Gloves

This is a step a lot of people unfortunately skip, but it's super important. Before every single use, you've got to check your insulated gloves. Look for any signs of damage: cracks, cuts, holes, or even excessive wear. You can do this by visually inspecting them and also by doing an air test – inflate the gloves with air and listen for any leaks. If you find any issues, the gloves are no longer safe to use and need to be replaced immediately. Keeping them clean and storing them properly, usually away from direct sunlight and heat, also helps them last longer and stay effective.

Beyond Gloves: Comprehensive Arc Flash Gear

While insulated gloves are a critical piece of the puzzle for electrical safety, they're just one part of a bigger picture when it comes to protecting yourself from arc flash hazards. Think of it like building a sturdy house – you need more than just a strong foundation; you need walls, a roof, and all the other bits to keep you safe and sound. The same applies here. When you're dealing with potentially dangerous electrical work, you need a full set of gear designed to shield you from the intense heat and force of an arc flash.

Face Shields and Head Protection

Your head and face are particularly vulnerable. An arc flash can send molten metal and superheated gases flying, and even a brief exposure can cause severe burns and eye damage. That's why specialized head and face protection is a must. This usually includes a hard hat to protect against impact and a full face shield that's rated for arc flash protection. These shields are made from materials that can withstand the heat and pressure, keeping your face and eyes out of harm's way. Some setups even include a balaclava or hood that covers your neck and ears, areas that are often overlooked but still at risk.

Arc-Rated Suits and Coveralls

For tasks with a higher potential for arc flash, you'll need more than just a basic shirt and pants. This is where arc-rated (AR) suits and coveralls come into play. These garments are made from special fabrics that are designed to resist ignition and melt away from the body when exposed to extreme heat. The level of protection is measured by its Arc Thermal Performance Value (ATPV), usually given in calories per square centimeter (cal/cm²). The higher the ATPV rating, the more protection the garment offers. You'll often see these suits categorized into different hazard risk categories (HRCs), with HRC 4 offering the highest level of protection.

Here's a general idea of how ATPV relates to hazard categories:

|

Hazard Risk Category (HRC) |

Typical ATPV Range (cal/cm²) |

|

HRC 1 |

4 - 8 |

|

HRC 2 |

8 - 25 |

|

HRC 3 |

25 - 40 |

|

HRC 4 |

40+ |

Footwear and Other Protective Accessories

Don't forget your feet! Standard work boots might not cut it. You need footwear that's specifically designed for electrical work, offering insulation and protection against slips and falls. Look for boots with electrical hazard (EH) ratings. Beyond that, there are other accessories that can add an extra layer of safety. This might include flame-resistant (FR) socks, specialized work shirts and pants worn under your AR suit, and even protective sleeves. Every piece of your gear needs to work together to create a complete barrier against potential hazards.

It's easy to think that just having one or two pieces of protective gear is enough, but when it comes to arc flash, you really need to cover all your bases. The energy released in an arc flash is incredibly powerful, and even small gaps in your protection can lead to serious injury. Always make sure your entire outfit is rated for the specific hazard level you're facing.

Conducting Arc Flash Hazard Analysis

So, you've got electrical equipment, and you're working around it. That means you need to know what could happen if something goes wrong, like an arc flash. That's where an arc flash hazard analysis comes in. It's not just some bureaucratic hoop to jump through; it's a serious look at the risks involved and how to protect yourself and others.

The Role of Arc Flash Analysis in Risk Mitigation

Think of an arc flash analysis as a safety roadmap. It helps identify potential dangers before they become real problems. By figuring out the possible arc flash energy levels, you can then determine what kind of protective gear is needed. This is super important for keeping workers safe, especially when dealing with energized equipment. It's all about being prepared and not just hoping for the best. Following standards like NFPA 70E is key here, as they lay out the requirements for these kinds of assessments.

Calculating Incident Energy Levels

This is where the numbers get crunched. Calculating incident energy involves looking at things like the available fault current, the distance from the equipment, and how fast the protective devices can clear the fault. The goal is to figure out how much thermal energy an arc flash would release at a specific working distance. This value, often measured in calories per square centimeter (cal/cm²), directly tells you how much protection you need. The closer you are to the potential arc source, the higher the incident energy will be, making that distance a really big factor.

Equipment Labeling Requirements

Once you've done the analysis, the results need to be clearly communicated. That's where equipment labeling comes in. Each piece of electrical equipment that could pose an arc flash hazard needs a label. This label should show the incident energy level and the required Personal Protective Equipment (PPE) category or rating. This way, anyone approaching the equipment can quickly see the potential danger and know what safety measures to take. It’s a visual reminder, right there on the equipment, of the risks and the necessary precautions.

Doing an arc flash analysis isn't a one-and-done deal. If you change how the protective devices are set up, or if you modify the equipment, you'll likely need to update the analysis and the labels. Safety standards evolve, and so should your assessments.

Here's a quick rundown of what goes into the analysis:

- System Information: Gathering details about the electrical system, like voltage and fault current.

- Equipment Assessment: Identifying equipment that needs analysis and its condition.

- Protective Device Settings: Understanding how circuit breakers and fuses are set.

- Working Distance: Determining the typical distance workers will be from the potential arc source.

- PPE Selection: Based on the calculated incident energy, specifying the required protective gear.

Ensuring Electrical Safety in the Workplace

Keeping everyone safe around electricity isn't just about having the right gear, though that's a big part of it. It's about building a whole system of safety practices. Think of it like this: you wouldn't just buy a fire extinguisher and call it a day for fire safety, right? You'd also have evacuation plans, regular drills, and make sure people know how to use the extinguisher. Electrical safety is pretty similar.

Training and Competency for Electrical Workers

First off, people working with electricity need to know what they're doing. This means proper training. It's not enough to just show up on the job; workers need to understand the risks, how to use tools safely, and what to do if something goes wrong. This includes knowing about things like arc flash hazards, which we've talked about, and how to protect themselves. Regular refreshers are a good idea too, because safety standards and best practices can change. Making sure your team is well-trained is probably the single most important step you can take.

Establishing an Electrically Safe Work Environment

This is a key concept, especially when you're dealing with equipment that might be energized. The goal is to make the equipment not energized before you start working on it. This involves a process called lockout/tagout (LOTO). You isolate the power source, lock it so no one can accidentally turn it back on, and tag it to show that work is being done. It’s a bit of a checklist, but a really important one.

Here’s a basic rundown of how it works:

- Identify all possible sources of electrical energy.

- Notify everyone who might be affected by the power being shut off.

- Shut down the equipment properly.

- Isolate the energy source (like opening breakers).

- Apply locks and tags to the isolating devices.

- Verify that the circuit is de-energized using a properly rated voltage tester.

- Test your voltage tester on a known live source before and after verifying the de-energized circuit.

Working on live electrical equipment should only be done when it's absolutely impossible to de-energize it, and even then, only with the highest level of PPE and strict procedures in place. The default should always be an electrically safe work environment.

JM Test Systems' Safety Solutions

Now, having good procedures and training is great, but you also need the right equipment to back it all up. That's where companies like JM Test Systems come in. They provide a whole range of gear designed to keep electrical workers safe. This isn't just about the big stuff like arc flash suits, but also includes things like insulated tools, testing equipment, and even accessories that help keep everything organized and ready to go. Having reliable safety equipment means you can trust that it will perform when you need it most. They've been around for a while, so they know what works and what doesn't in the real world of electrical work.

Staying Safe with the Right Gear

So, we've talked about arc flashes and why they're a big deal. It's clear that having the right protective gear, like those special gloves and suits, is super important for anyone working with electricity in Johor. Following the rules, like those from NFPA 70E, and making sure you have the correct gear for the job can really make a difference. Don't cut corners when it comes to safety – it's not worth the risk.

Frequently Asked Questions

What exactly is an arc flash and why is it so dangerous?

An arc flash is like a super-powerful, uncontrolled electrical explosion. It happens when electricity jumps through the air between two conductors or from a conductor to the ground. This creates a bright flash and a very hot burst of energy, which can cause severe burns, blindness, and even death. It's incredibly dangerous because of the intense heat and the force of the blast.

How close do you need to be to an arc flash for it to be harmful?

Even being 18 inches away from an arc flash can expose you to dangerous levels of heat. The closer you are to the source of the arc flash, the more intense the heat and blast become. This means that even if your protective gear is rated for a certain distance, being closer than that can still cause serious harm.

What is Arc Thermal Performance Value (ATPV) and why is it important for clothing?

ATPV is a rating that tells you how much heat a piece of clothing can handle before it starts to break down and let the heat through. It's measured in calories per square centimeter. The higher the ATPV number, the better the protection. This rating is crucial for choosing the right flame-resistant clothing to protect you from arc flashes.

Besides gloves, what other protective gear is needed for arc flash safety?

Gloves are just one part of the puzzle! You also need things like a special helmet with a face shield to protect your face and eyes, flame-resistant (FR) clothing like suits or coveralls, and protective footwear. Think of it as a full suit of armor against electrical hazards.

What are the rules about electrical safety, like NFPA 70E and OSHA?

NFPA 70E and OSHA are like the rulebooks for electrical safety. NFPA 70E provides guidelines for how to work safely around electricity, including what kind of protective gear to use and how to analyze the risks. OSHA is a government agency that enforces safety standards in the workplace. Following these rules helps prevent accidents and injuries.

How often should electrical workers be trained on safety procedures?

It's really important for electrical workers to stay up-to-date on safety. Regulations like NFPA 70E suggest that workers should be retrained at least every three years. This ensures they remember the best practices and are aware of any new safety information or equipment.